An Ultimate Guide to Thermal Paper Specifications

From retail, hospitality, healthcare to logistics, thermal paper is an indispensable part of many industries. With its unique coating and heat reactive properties, it’s a must have for printing receipts, labels and tickets. For optimal performance, it is important to know the specifications that make thermal paper a quality and usable product. This guide gives you all the information you need to know about thermal paper specifications and make informed decisions for your business needs.

What Is Thermal Paper?

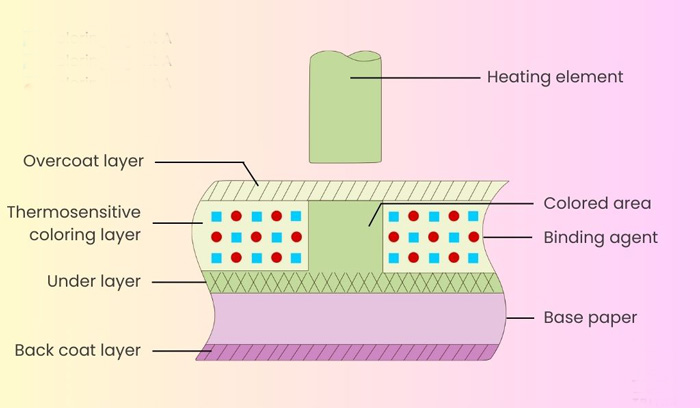

Thermal paper is a paper that is specially coated so it reacts to heat to produce images or text. Thermal printing doesn’t require ink or toner the way traditional printing does. Instead, a thermal printer simply heats up the paper enough to activate the coating and print.

Key Specifications of Thermal Paper

Paper Weight

Thermal paper is measured by weight in grams per square meter (gsm). Lighter paper is more economical, heavier paper has durability and better print quality. Common weights are from 48 gsm to 80 gsm.

Paper Thickness

The thickness of paper is measured in microns and determines how sturdy the thermal paper is. The standard thicknesses vary from 50 to 100 microns depending on the application. Thicker paper is often used.

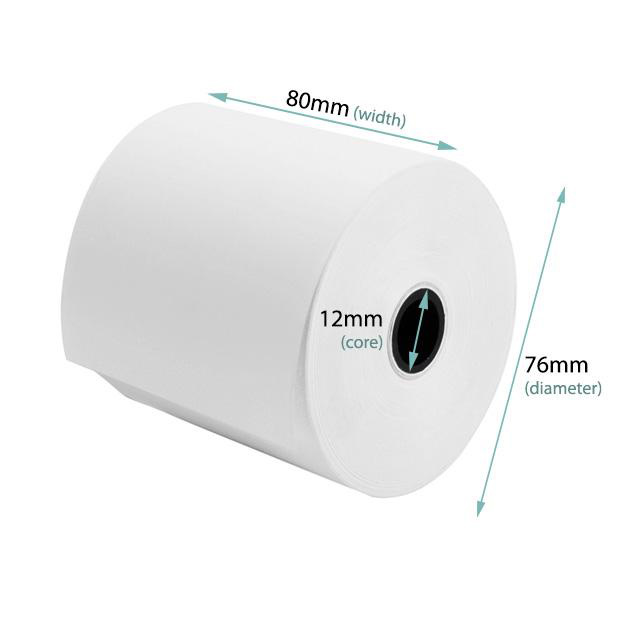

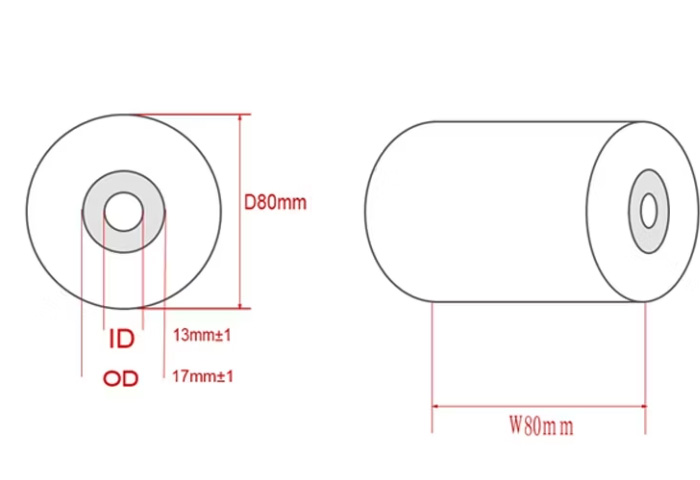

Roll Dimensions

Thermal paper rolls are available in different widths and lengths for different printer models. Key dimensions to consider are:

- Width: It ranges from 44mm to 80mm typically.

- Core Size: The diameter of the roll’s core, usually 12mm or 25mm.

- Length: The thickness of the paper and core size depends mostly between 10m to 100m.

Coating and Sensitivity

Thermal paper has a heat sensitive layer that gets coated on it, and it reacts to the printer’s thermal head. Less heat is needed for printing with high sensitivity paper, which extends the printer’s lifespan and also makes the printer more energy efficient.

Durability and Archival Life

Thermal paper durability refers to how long the print remains legible under normal conditions. Some papers are designed for short-term use (e.g., receipts), while others have archival qualities, retaining print for up to 25 years. Factors affecting durability include:

- Exposure to heat, light, and moisture.

- Storage conditions.

BPA-Free and Eco-Friendly Options

Health and environmental concerns have led to the development of BPA-free thermal paper. This type uses alternative chemicals, ensuring safety without compromising quality. Additionally, eco-friendly options include recyclable or FSC-certified paper.

Applications and Choosing the Right Thermal Paper

Thermal paper is tailored for specific uses, such as:

- Receipts: Standard durability lightweight paper.

- Labels: Shipping and product tagging adhesive backed paper, durable.

- Tickets: Longer lasting and heavier paper for use as event or parking tickets.

When selecting thermal paper, consider:

- Printer compatibility.

- Required durability.

- Environmental regulations.

How to Test Thermal Paper Quality

To ensure you’re using high-quality thermal paper:

- Perform a print test: Make sure you get clear, sharp and consistent print results.

- Conduct durability tests: The paper is exposed to heat, light, and humidity to evaluate its performance.

- Inspect coating consistency: Patchy prints can be due to uneven coating.

Conclusion

It’s important to understand thermal paper specifications in order to purchase the right product for your business. Performance and cost are dependent on each specification from weight and thickness to durability and eco friendliness. Choosing high quality thermal paper for your needs can help you be more efficient, save money and help the environment.

Top Roll Paper offers a range for premium thermal paper solutions. Our products are of the highest quality and most reliable.